Training the next generation and taking care of our own.

NCIFTI is an accredited educational institution offering attractive career pathways in the finishing trades.

North Central Illinois Finishing Trades Institute: Painters District Council No. 30

The North Central Illinois Finishing Trades Institute is an apprenticeship & training program for the occupations of Painter-Decorator, Drywall Finisher (Taper), Glazier and Industrial Coating & Lining Application Specialist (CAS). Located in Aurora, Illinois, the NCIFTI trains craftspersons belonging to Painters District Council No. 30. Providing a program and facility for apprenticeship and training is made possible by contributions from all active members based on their hours worked, and the Painters District Council No. 30 Pension Fund, which owns and operates the new state-of-the-art facility.

FACILITY

North Central Illinois Finishing Trades Institute

ButtonApprenticeship & Training Office

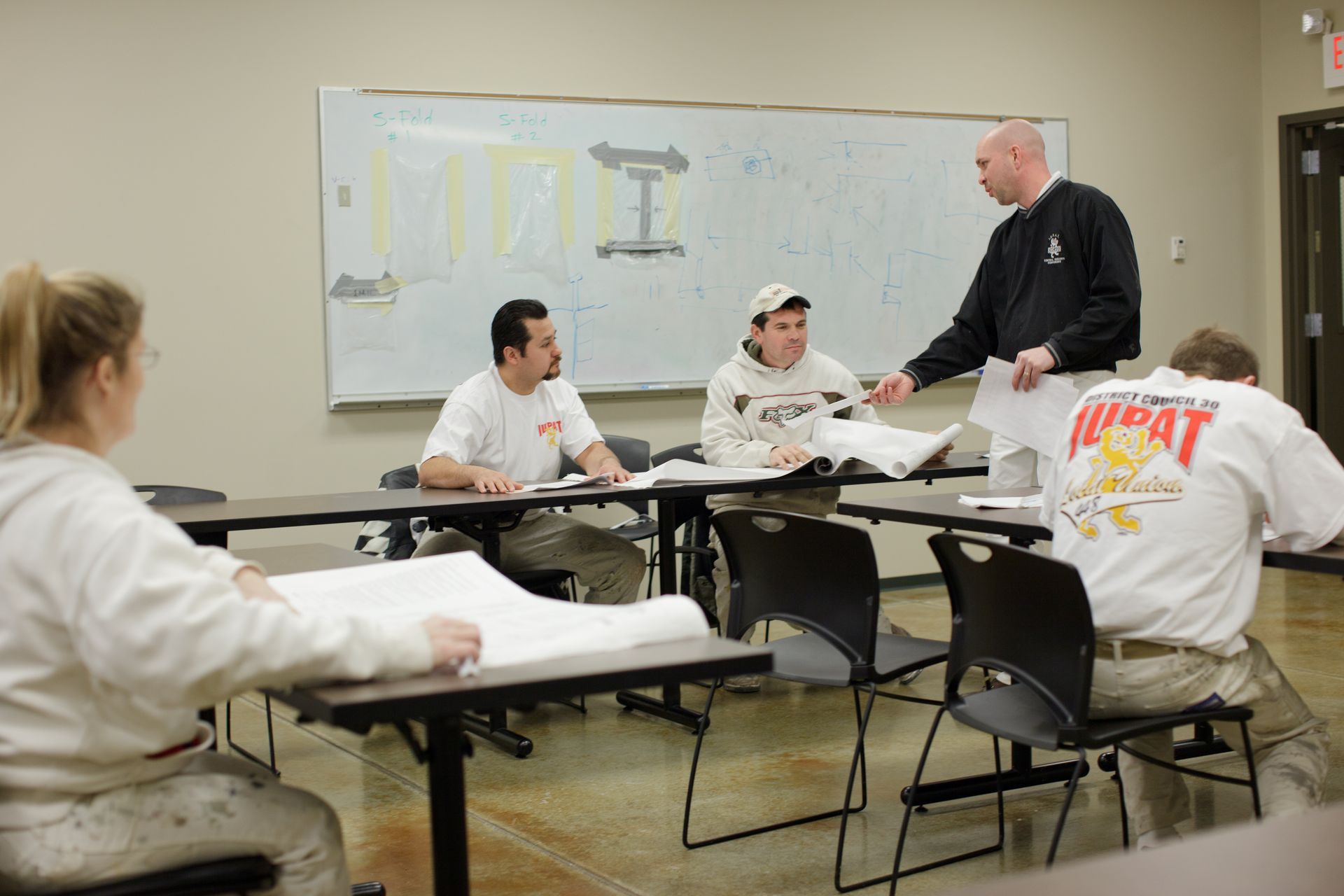

ButtonDrywall class training

ButtonTraining

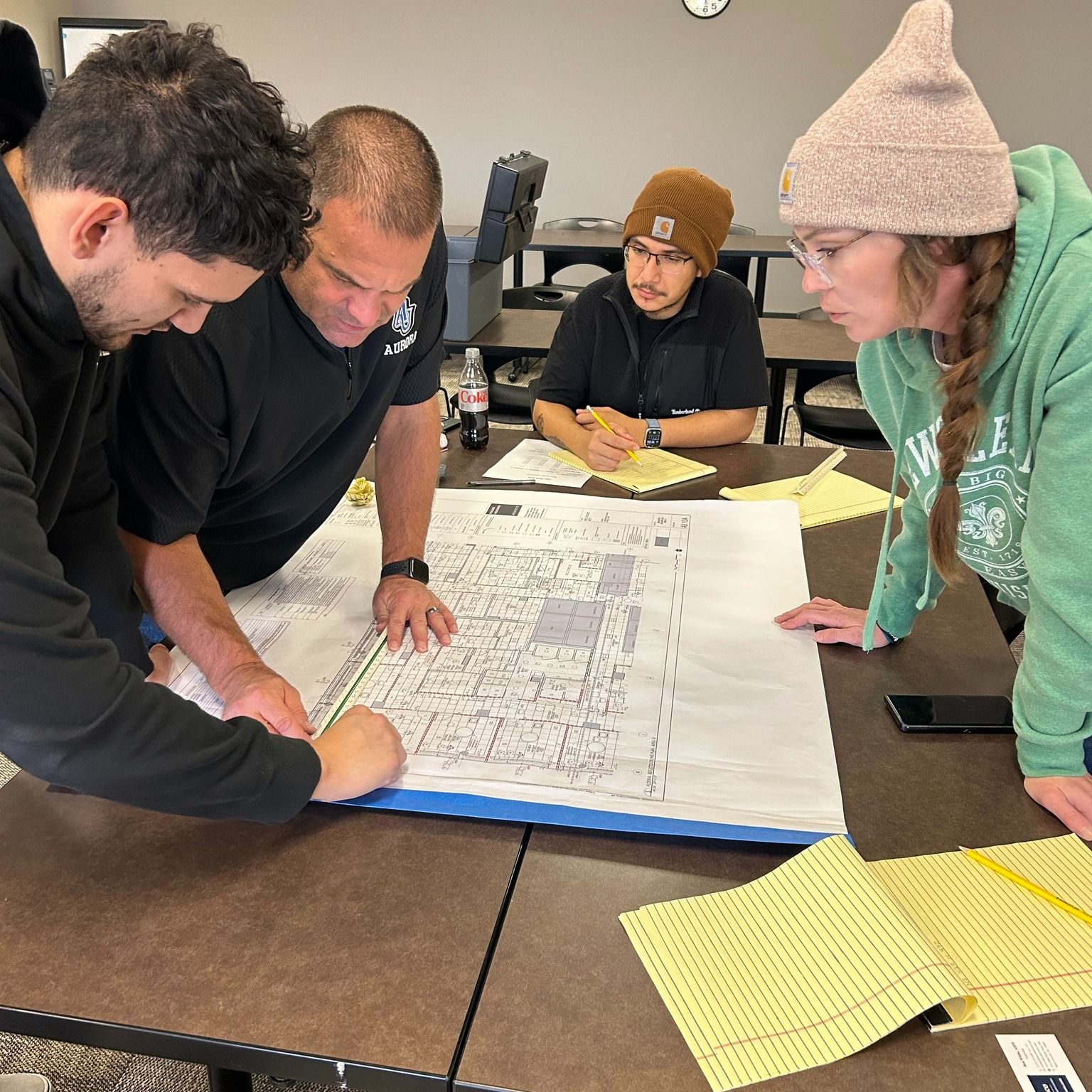

ButtonClassroom training

ButtonFacility training areas

ButtonTraining facility area

ButtonClassroom training

ButtonClassroom training with paint colors

ButtonTraining facility blasting booth

ButtonTraining facility area

ButtonTraining facility rooms

ButtonApprenticeship programs

Open the sections below for course information, or download the student handbook.

Core Curriculum Modules

The Core (COR) Curriculum Modules of the NCIFTI are designed to provide a foundation on which all apprentices in multiple trades will be exposed to a uniform body of theoretical knowledge and practical skills needed to be a successful tradesperson in the finishing trades. Each of NCIFTI’s Apprenticeship Programs require the completion of Core Curriculum Modules described below:

COR 1 – Introduction to the Finishing Trades.

This introductory-level module will familiarize students with elements of an apprenticeship in the Finishing Trades. Topics include NCIFTI program orientation; history of organized labor and the International Union of Painters and Allied Trades; introduction to union membership; respirator fit; and OSHA construction and safety awareness focusing on identifying hazards, safe work practices, and accident/injury prevention.

COR 2 - Leadership and Professional Development.

The Leadership & Professional Development module is designed to prepare students for a successful career as a union finishing trades worker. Topics include understanding the cooperative and strategic relationship between union leaders, contractors, end users, and trades workers; strengthening skills to maintain open communication and develop professional working relationships with other individuals on a jobsite; understanding the role of a jobsite Foreman; basic math review including measurements, fractions, decimals, percentages, angles, and estimating; reading blueprint specifications; basic computer skills using Microsoft Office; instructions in personal finance/money management; and building a resume to secure reliable employment.

COR 3 - Health & Safety in the Finishing Trades

The Health and Safety in the Finishing Trades module is designed to equip students with the certifications and training necessary to maintain a safe work atmosphere, prevent accidents/injuries, respond to emergencies, and identify hazards on the job. Topics include effectively performing First Aid, CPR, and AED skills; recognizing potential fall hazards and understanding the proper use of fall protection equipment; developing safe work habits while working on elevated temporary platforms/scaffolds; selecting and handling swing stage equipment in a safe and efficient manner; identifying aerial lift precautions, rules, and emergencies and demonstrating the proper operation of boom and scissor lifts; recognizing hazardous substances and communicating hazard information on a jobsite; and learning the proper removal of lead-based painted surfaces.

Painter - Decorator Program

The term of Apprenticeship for the Painter-Decorator shall be a minimum of 3 years of reasonably continuous employment, a minimum of 4650 hours of On-the-Job learning and successful completion of 3 Core (COR) Curriculum Modules and 9 Painter-Decorator (PNT) Curriculum Modules, for a total 12 Curriculum Modules of Related Technical Instruction (RTI) at the NCIFTI.

PNT 1 – Introduction to the Painting and Decorating Trade

The intro to the Painting and Decorating Trade module is designed to introduce students to the fundamentals of the painting and decorating trade. Topics include demonstrating proper use of basic wallcovering tools and painting equipment; demonstrating application techniques and proper care and cleaning of tools; using a masking machine, drop cloth, and liquid masking to protect adjacent surfaces; applying appropriate masking techniques for different projects and surfaces; and recognizing the proper surface preparation for painting interior and exterior wood substrates.

PNT 2 - Paint Materials and Coatings

The Paint Materials and Coatings module is designed to familiarize students with identifying and applying basic coatings and finishes. Topics include completing a pre-job walk-through; understanding the safety, record-keeping, communication, and environmental issues to address during a pre-job analysis; recognizing wood finishing equipment, materials, procedures, and terminology; using caulking to close joints and gaps, provide thermal insulation, control water penetration, and reduce noise mitigation; recognizing surface deterioration on wood, metal, masonry, concrete, plaster, and drywall substrates; identifying factors that cause paint failures and remedies for abnormal surface deterioration; identifying paints, coatings, and materials; and understanding the procedures for selecting, mixing, and handling solvents.

PNT 3 - Color Mixing and Matching

The Color Mixing and Matching module is designed to equip students with the ability to mix the proper paint bases and universal colorants to match decorative color schemes while improving their hand application skills. Topics include demonstrating the use of the color wheel; understanding how light is related to colors and hues; developing shades, tints, and tones; recognizing the difference between gloss and reflectance; and describing the use of color in decorating for residential, business, and industry settings.

PNT 4 - Airless Spray Systems

The Airless Spray Systems module is designed to introduce students to the fundamentals of spray painting. Topics include understanding the basics of the various spray systems; recognizing potential hazards and applying preventative measures when operating spray equipment; describing hazardous conditions that can lead to fire, explosion, skin injection, electric shock, moving part injuries, and toxicity; identifying spray painting techniques, terminology, and components using each type of spraying system; developing fundamental spray painting techniques and safe work practices in a virtual environment; understanding the principles, safety precautions, and use of an airless spray system; and demonstrating how to properly set up, operate, disassemble, and reassemble an airless spray pump.

PNT 5 - Wood Finishing w/Conventional and HVLP Spray Systems

The Wood Finishing w/Conventional and HVLP Spray Systems module is designed to provide students with the fundamentals of Wood Finishing and practical experience using air spray systems. Topics include understanding the function of compressors in a conventional air spray system; recognizing the major components of an HVLP system; performing maintenance on HVLP system equipment; operating conventional HVLP systems in compliance with OSHA regulations; mixing paints for HVLP spray applications; analyzing specifications to determine the quality and characteristics of wood finishes; using various wood finishing tools and materials; demonstrating proper wood sanding, bleaching, sealing, staining, and glazing techniques; and practicing various wood finishing procedures.

PNT 6 - Industrial Painting and Abrasive Blasting

The Industrial Painting and Abrasive Blasting module is designed to introduce painting and decorating students to the basic elements of the industrial painting trade. Topics include recognizing coating materials, tools, equipment, and terminology of the industrial applicator; identifying and controlling corrosion; understanding instructions, techniques, and standards relevant for inspecting coating applications; differentiating between quality control and quality assurance; learning to recognize, evaluate, prevent, and abate safety and health hazards associated with working in a confined space environment; recognizing the primary elements of an abrasive blast cleaning system; practicing hands-on virtual blasting; selecting the appropriate coating application method; operating airless spray systems and troubleshooting spray pattern problems; practicing common knots used in industrial painting; and planning and staging a proper containment.

PNT 7 - Drywall Finishing and Repairs for Painters

The Drywall Finishing and Repairs for Painters module is designed to provide painting and decorating students with a basic understanding of drywall finishing and drywall repairs. Topics include identifying drywall fasteners, adhesives, tapes, and compounds; describing the procedures for repairing various wallboard defects; demonstrating the hand taping process; describing the taping process using the dry taping, hopper tape, and banjo tape methods; demonstrating the procedure for wiping angles and correcting common problems that arise while wiping angle tapes; demonstrating the functions, operations, and procedures for using flat and angle finishing boxes; and understanding the parts, functions, safety, sequences, and maintenance procedures of automatic taping tools.

PNT 8 - Wallcovering and Special Decorative Finishes

The Wallcovering and Special Decorative Finishes module is designed to introduce students to the fundamentals of wallcovering and decorative finishes. Topics include recognizing the various types, tools, equipment, and use of wallcovering; demonstrating wallcovering removal, surface preparation, application, and repair; recognizing various types, purposes, products, and tools of decorative finishing; and applying various decorative finishes to a substrate.

PNT 9 - Advanced Wallcovering

The Advanced Wallcovering module is designed to provide students with additional experience in and comprehension of the wallcovering trade. Topics include identifying specific properties of each type of covering; removing old wallcovering using three removal methods; estimating the correct amount of wallcovering for a space; recognizing problems when preparing and handling wall coverings; using efficient procedures and best techniques in applying wallcoverings; and installing wallcoverings and borders in difficult places.

Drywall Finisher (Taper) Program

The term of Apprenticeship for the Drywall Finisher (Taper) shall be a minimum of 3 years of reasonably continuous employment, a minimum of 4650 hours of On-the-Job learning and successful completion of 3 Core (COR) Curriculum Modules and 9 Drywall Finisher (DRY) Curriculum Modules, for a total 12 Curriculum Modules of Related Technical Instruction (RTI) at the NCIFTI.

DRY 1 – Introduction to the Drywall Finishing Trade

The Introduction to the Drywall Finishing Trade module is designed to introduce students to the fundamentals of the drywall finishing trade. Topics include identifying and handling drywall tools; performing jobsite inspections on electrical, plumbing, construction framing, and insulation work; demonstrating safe work practices and proper technique on a job; understanding the characteristics, formulations, types, and uses of filling compounds; demonstrating the taping process using the dry taping, hopper tape, and banjo tape methods; using the trowel method to fill rounded surfaces, ceilings, walls, angles, joints, and beads; using stilts, ladders, and scaffolds; and demonstrating the procedure for wiping angles and correcting common problems that arise while wiping angle tapes.

DRY 2 – Hand Finishing Fundamentals

The Hand Finishing Fundamentals module is designed to provide students with a more in-depth understanding of taping by hand. Topics include describing the operation of mixing fillers; understanding how variables in temperature and humidity affect the finishing process; learning the broadknife method of filling by hand; choosing the proper method for filling rounded surfaces, ceilings, walls, angles, joints, and beads; and demonstrating the procedure for wiping horizontal, vertical, and three-way angles with a Corner Finisher and by hand. This module also includes an introduction to painting for drywall finishers, which provides an overview of the basic types of wallcovering and painting equipment.

DRY 3 – Fast-Setting Compounds, Finishing Box and Drywall Repairs

The Fast-Setting Compounds, Finishing Boxes, and Drywall Repairs module is designed to introduce students to the basic elements of fast-setting compounds and other hand taping efficiencies. Topics include demonstrating proper efficiency when working with fast-setting compounds; explaining expected compound drying times according to material, weather, and filling process; improving hand taping efficiency with special emphasis on work quality, safety, and longevity; demonstrating the functions, operations, and procedures for using flat and angle finishing boxes; applying tape on corner beads with fast-setting joint compounds; describing the procedures for repairing various wallboard defects; and preparing a level 3 surface to sand and paint. This module also includes a paint materials and colors topic for drywall finishers, which introduces the composition and properties of basic paint materials and their appearances.

DRY 4 - Introduction to Automatic Taper and Specialty Beads

The Introduction to Automatic Taper and Specialty Beads module is designed to familiarize students with the basic elements of automatic taping tools. Topics include understanding the parts, functions, safety, sequences, and maintenance procedures of automatic taping tools; demonstrating the proper use of AMES Automatic Taping & Finishing Tools, Bazookas, and the First Box process; perfecting hand-taping and filling-by-hand techniques for any work environment; understanding the typical tape-and-coat application process most commonly used on the job; and demonstrating the ability to embed, join, and fill bullnose and chamfer corner bead.

DRY 5 - Automatic Taping Tools and Textures

The Automatic Taping Tools and Textures module is designed to provide students with more in-depth knowledge of automatic taping tools and skills development along with an introduction to the application of textures. Topics include understanding the importance of direct tool-to-wall tape application skills, cleanliness, and efficiency; recognizing the fundamental differences between traditional and ergonomic finishing boxes; demonstrating how to properly and safely setup, operate, and clean taping tools; identifying powdered and pre-mix forms, aggregated and non-aggregated materials, and selecting the appropriate texture materials to apply hard hand textures; and understanding the fundamental working principles of drywall finishing tools for effective troubleshooting, adjustments, or repairs.

DRY 6 - Basic Paint Application for Drywall Finishers

The Basic Paint Application for Drywall Finishers module is designed to provide drywall finishing students with additional experience in basic cut-and-roll paint application techniques to better understand the effects that paint has on finished drywall surfaces. Topics include demonstrating proper selection of tools and materials needed to complete drywall repairs in a short period of time; developing proficiency in preparing surfaces to be primed and painting surfaces using flat and glossy coatings; combining understandings of fast-setting joint compounds and finishing box operations to apply multiple coats of fast-setting joint compound in one session; and enhancing positive work habits and efficiencies using an automatic taping tool.

DRY 7 - Specialties of the Drywall Trade

The Specialties of the Drywall Trade module is designed to familiarize students with various specialties of the trade, including texturing, spray applications and repairs. Topics include understanding Exterior Insulation and Finish Systems and identifying properly installed substrate materials, conditions, and preparation; identifying different types of texturing machines and using spray application of knockdown, splatter, orange peel, and acoustic textures; and conducting sanding, spot priming, and paint touch-up upon completion of drywall repairs. This module also includes an introduction to spray application for drywall finishers, which provides an overview of airless spray system fundamentals and safe operation procedures

DRY 8 - Advanced Drywall Finishing Applications

The Advanced Drywall Finishing Applications module is designed to provide students with an advanced comprehension of the drywall finishing trade. Topics include improving taping productivity through speed and maintenance; demonstrating how to properly apply, burnish/polish, and seal Venetian Plaster; learning to problem solve trouble areas to produce blemish-free surfaces; recognizing the different Levels of Finish; identifying materials, application methods, and operating procedures for a Level 5 Application; and understanding the decorative beads, mud set, corner beads, commercial beads, and Trim-Tex products necessary for Drywall Art applications.

DRY 9 – Process Reinforcement Verification

The Process Reinforcement Verification module is designed to provide students with additional training to perfect advanced drywall finishing skills. Topics include understanding general firestopping information and trade-specific installation details; explaining various factors to be considered when determining taping methods and materials; understanding floor plans, specifications, and building codes; recognizing noise control and absorption materials and their installation methods; demonstrating how to properly operate an automatic taper with minimal guidance; demonstrating the proper application of select hand and spray textures without assistance; and demonstrating how to perform a level 3 hand applied fast-setting joint compound in one session.

Glazier Program

The term of Apprenticeship for the Glazier Program shall be a minimum of 3 years of reasonably continuous employment, a minimum of 4650 hours of On-the-Job learning and successful completion of 3 Core (COR) Curriculum Modules and 9 Glazier (GLZ) Curriculum Modules, for a total 12 Curriculum Modules of Related Technical Instruction (RTI) at the NCIFTI.

GLZ 1 - Introduction to the Glazing Trade

The Introduction to the Glazing Trade module is designed to introduce students to the fundamentals of the glazing trade. Topics include understanding federal and local glazing laws and statutes; identifying safety glazing products and determining when to use safety glazing materials; demonstrating basic math skills as they apply to the glazing trade; recognizing the types, varieties, safety guidelines, and functions of basic glazing hand tools; identifying and practicing glass cutting techniques using various tools and machinery; reducing the risk of fire, electric shock, and personal injury when using shop machinery; understanding the procedure and safety guidelines for removing broken glass; and demonstrating the sealing and installation of a lite of glass using putty as a sealing compound.

GLZ 2 - Architectural Drawings

The Architectural Drawings module is designed to assist students in reading and understanding job specification plans and drawings. Topics include identifying symbols, abbreviations, and lines found on a set of plans and drawings; understanding the fractional rule, the architect’s scale, and the engineer’s scale; calculating measurements and determining the length of a scaled line; sketching technical drawings with the use of instruments, scales, and mechanical equipment; using perimeter sheets to obtain job specification details; reading and interpreting shop drawings to understand fabrication/installation; studying architectural drawings to learn how to accurately interpret drawings for any type of structure; and learning to measure, fabricate, and install mirrors.

GLZ 3 - Sealants and Layouts

The Sealants and Layouts module is designed to familiarize students with the basics properties and applications of sealants and proper layout procedures for glazing installations. Topics include demonstrating the best method for installing mirrors; reading, and understanding the components of contract documents and specifications for all crafts; understanding processes for applying anodized and painted coatings on aluminum surfaces; demonstrating the proper procedures to handle, clean, and store anodized or painted aluminum; using and reading transits and leveling instruments; recognizing terminology, selection factors, forms, classifications, and properties of sealants; and performing work related to joint design, sealant selection, substrate preparation, and sealant application.

GLZ 4 - Curtain Wall Systems

The Curtain Wall Systems module is designed to provide students with a basic understanding of curtain wall systems and their installation methods. Topics include demonstrating proper joint cleaning, priming, and sealant installation techniques; evaluating the general procedures used by manufacturers to test sealants for quality; developing a basic understanding of curtainwall methods, standards, handling techniques, and safe working practices; recognizing the components of structural glazing systems including safety considerations, and proper surface preparation; interpreting the MSDS requirements for primers, solvents, and sealants used in structural glazing applications; demonstrating silicone sealant application techniques for structural glazing; using blocks, spacers, tapes, and gaskets to prevent glass breakage, weather damage, and glass failure; recognizing various types of hinges, pivots, closers, and accessories designed for installing doors; and recognizing materials commonly used in storefront installation.

GLZ 5 - Door and Hardware Schedule

The Door and Hardware Schedule module is designed to introduce students to the elements of installing various types of doors and hardware systems. Topics include following hardware guidelines and understanding proper door installation for public and/or commercial buildings; recognizing the terminology and mechanics associated with locks and bolts; understanding the purpose, basic types, terminology, and installation of panic hardware; identifying weatherization principles, purpose, equipment, maintenance requirements, and job site practices; understanding pressure wall components, terminology, fabrication techniques, and installation; and an introduction to skylights and sloped glazing systems.

GLZ 6 - Skylights and Sloped Glazing Systems

The Skylights and Sloped Glazing Systems module is designed to provide students with an in-depth understanding of skylights and other various types of glazing panels. Topics include understanding the various applications, terms, and types of glass used for skylights and sloped glazing systems; recognizing the roles and responsibilities for skylight operations from fabrication to installation; using Material Safety Data Sheets; selecting sealants and understanding the importance of sealant-substrate compatibility; performing sealant adhesion testing in the field; demonstrating proper handling, storing, fabrication and installation of spandrel and porcelain glazing panels; and recognizing the terminology, components, fabrication, and installation of insulated and high performance glass.

GLZ 7 - Photovoltaic Systems

The Photovoltaic Systems module is designed to introduce students to solar energy panels and other specialized glazing systems. Topics include identifying commonly used types of security glass and their suggested applications; demonstrating installation and safety procedures for aquariums, shower doors, tubs, and showcases; identifying three basic ribbon window systems and their fabrication and erection techniques; understanding types, purpose, and use of plastics in glazing applications; navigating the details of a perimeter sheet; and identifying the materials, components, and connections required to make a complete photovoltaic system.

GLZ 8 – Shielded Metal Arc Welding I

The Shielded Metal Arc Welding I module is designed to familiarize students with a basic understanding of construction shielded metal arc welding. Topics include examining the fundamentals of the Shielded Metal Arc Welding (SMAW) process; identifying industries and applications where welding processes are performed; recognizing welder safety and working conditions; defining welding terminology and interpreting welding symbols established by the American Welding Society; striking the arc using the scratch-start method; and depositing stringer beads in a continuous, consistent fashion.

GLZ 9 – Shielded Metal Arc Welding II

The Shielded Metal Arc Welding II module is part 2 in the series, designed to provide students with more in-depth knowledge of construction shielded metal arc welding. Topics include striking the arc using the scratch-start method with various electrodes; demonstrating proper low hydrogen starts, stops, and restarts; using various electrode and stringer bead techniques to weld multiple layer projects with a uniform overlay and proper bead fusion; depositing stringer beads in vertical and overhead positions; explaining the use of oxyfuel cutting equipment; demonstrating the proper set-up, lighting, adjustment, and shut-down of oxyfuel equipment; and welding overhead plates to 4G Certification specifications.

Painter - Industrial Coating & Lining Application Specialist (CAS) Program

The term of Apprenticeship for the Industrial Coating & Lining Application Specialist (CAS) Program shall be a minimum of 3 years of reasonably continuous employment, a minimum of 4650 hours of On-the-Job learning and successful completion of 3 Core (COR) Curriculum Modules and 9 Industrial Coating & Lining Application Specialist (CAS) Curriculum Modules, for a total 12 Curriculum Modules of Related Technical Instruction (RTI) at the NCIFTI.

CAS 1 - Introduction to the Industrial Painting Trade

The Introduction to the Industrial Painting Trade module is designed to introduce students to the basic elements of the industrial painting trade. Topics include identifying and controlling corrosion; recognizing coating materials, tools, equipment, and terminology of the industrial applicator; understanding occupational noise exposure and practicing other communication strategies; recognizing the importance of steel surface preparation and the principles of abrasive blast cleaning; preventing jobsite hazards for the industrial applicator; understanding ambient conditions and their effect on application and coating performance; using stripe coating to provide extra corrosion protection measures on irregular steel surfaces; and understanding quality tests, standards, and tools used to check coating application on the job.

CAS 2 - Airless Spray Systems

The Airless Spray Systems module is designed to introduce students to the various coating application methods and determining the correct application for each job. Topics include learning proper storage, mixing, and thinning techniques; understanding procedures and formulas used to achieve desired film thickness; identifying airless spray terms and equipment components; demonstrating the ability to properly operate an airless spray system; and troubleshooting spray pattern problems.

CAS 3 - Nozzle Blasting Systems

The Nozzle Blasting Systems module is designed to introduce students to the primary components of air abrasive blast cleaning nozzle equipment. Topics include recognizing the primary elements of an abrasive blast cleaning system; understanding nozzle blast safety systems and employing tips to enhance productivity; demonstrating the ability to abrasive blast clean a surface to a desired cleanliness level; identifying various abrasive media and their influences on cleaning levels, productivity, and surface profile; recognizing SSPC abrasive specifications; demonstrating proper sand blasting techniques using a virtual nozzle blasting simulator; and learning to identify, maintain, and properly size various types of dust collector units.

CAS 4 - Bridge Rigging & Containment

The Bridge Rigging and Containment module is designed to familiarize students with various bridge structures and their integral parts and specifications. Topics include understanding the importance of coatings in corrosion mitigation; learning to secure safety lines and material lines using different knot tying skills and recognizing the correct application of each knot type; demonstrating the proper installation of bridge rigging equipment, including the ability to rig a horizontal steel cable; understanding the various techniques, tools, and materials used for building containments systems; and following containment specifications to build a properly ventilated containment system.

CAS 5 - Quality Control, Spray Applications and Welding

The Quality Control, Spray Applications and Welding module is designed to introduce students to quality control standards, conventional spray components, and welding safety considerations. Topics include demonstrating proper application techniques with a focus on dry film thickness, adhesion, and discontinuities; understanding instructions, techniques, and standards relevant for inspecting coating applications; differentiating between quality control and quality assurance; identifying the basic mechanisms of corrosion control and film formation; identifying the components and the correct procedure required to apply coatings using conventional spray systems; introduction to air-assisted airless spray and electrostatic spray applications; maintaining and verifying the accuracy and calibration of inspection equipment; and learning the basics of the Shielded Metal Arc Welding (SMAW) process.

CAS 6 - Storage Tank Rigging and Containment

The Storage Tank Rigging and Containment module is designed to familiarize students with the access, containment, and rigging processes for coatings application on industrial storage tanks. Topics include demonstrating the proper assembly, operation, and maintenance of tube and coupler scaffolding for work surfaces with irregular dimensions; building containment around scaffolding; identifying industrial project hazards; developing an access plan and properly rigging an access system; and learning multiple containment systems associated with tank coating projects to reduce debris and overspray.

CAS 7 – Concrete Coating Specialties

The Concrete Coating Specialties module is designed to introduce students to coating, treating, and repairing various concrete surfaces. Topics include recognizing the properties of concrete, mix components, and concrete surface preparation standards; learning the proper methods for transporting, placing, and finishing concrete; treating concrete irregularities; understanding the components and operation of portable centrifugal (wheel) abrasive blast cleaning equipment; and identifying the characteristics and materials used in Broadcast Flooring, Slurry Coat Systems, and Troweled Polymer Systems.

CAS 8 - Temporary Work Platforms and Spray Specialties

The Temporary Work Platforms and Spray Specialties module is designed to introduce students to the Multi-Span Bridge Platform Systems and Specialty Spray Systems. Topics include recognizing the various elements of and properly installing a Safe Span System; identifying troubleshooting procedures and installation hazards concerning Safe Span Systems; understanding the various elements of a chain link fence suspended temporary scaffold system, including proper installation, troubleshooting procedures, installation hazards, and associated tools; recognizing the primary components of a plural component spray operation system and understanding the spray technology methods; understanding the information required in the documentation of the inspection process; identifying the processes used to measure and monitor work results during and after the application process; and understanding Waterjetting equipment, standards, and surface preparation requirements.

CAS 9 - Coating Application Specialist

The Coating Application Specialist module is designed to equip students with the training and preparation necessary to test for and achieve SSPC certification as a Coating Application Specialist (CAS), enabling trades workers to successfully prepare and apply protective coatings to complex industrial structures. Topics include reviewing the identification and control of corrosion; reviewing quality tests and standards used to check coating application on the job, including hands-on use of all quality control instruments in preparation for the CAS Exam; reviewing the primary elements of abrasive blast cleaning and airless spray systems and their operation; identifying the key concepts of the Industrial Applicator Training Program covered on the SSPC CAS examination; and achieving SSPC Certified Application Specialist certification.

Continuing Education

Safety Training Awards Recognition

STARs, or Safety Training Awards Recognition, is an incentive program that rewards members who take advantage of our continuing education classes in health and safety. Qualifying STARs finalists are honored during an annual member appreciation picnic, which includes lunch, carnival games and activities, live entertainment, raffle drawings, and a wellness fair.

Members who meet the requirements outlined in the official program rules will automatically receive a customizable STARs Prize Package. Those who meet the additional Secondary Grand Prize requirements will be eligible for a chance to win their choice between a variety of prize package options, including new household appliances, a home theater system, a new fishing boat, a new ATV, a Disney vacation, or a Hawaiian island vacation. Furthermore, journey workers who meet the Grand Prize requirements will be entered into a drawing for their choice of vehicle from Gerald Ford in North Aurora.

To become eligible for awards, earn at least two STARs course credits and work at least 500 continuous hours during each calendar year, beginning January 1st and ending December 31st.

Notice

Reaffirmation of Accreditation

The North Central Illinois Finishing Trades Institute (NCIFTI) is applying for reaffirmation of accreditation with the Commission of the Council on Occupational Education. Persons wishing to make comments should either write to the Executive Director of the Commission, Council on Occupational Education, 7840 Roswell Road, Building 300, Suite 325, Atlanta, Georgia 30350, or submit their comments through the Council’s website (www.council.org). Persons making comments must provide their names and mailing addresses.